PRODUCT DETAILS

PRODUCT DETAILS

Stirring and mixing are two of mankind's oldest basic operations. Their origin can be traced back to the earliest days of food preparation. When preparing soup, a spoon is required to stir the pot. The spoon used for this process is the mixing tool and the circular hand movement is the mixing drive unit.

Even the very first mixing processes required empirical experience in order to achieve the desired result.

Mixing is the process of combining several different source materials in conjunction with energy input. The multitude of the substances to be mixed is hard to estimate due to varied states of aggregation, composition, chemical and physical characteristics. Substance parameters such as density or powder density and viscosity, carry great significance during the mixing process. These parameters determine the energy requirements, the possible miscibility, the dispersing degree, and the mixture's stability.

Today, laboratory mixing devices and tools are used worldwide to perform the following basic operations:

* Dissolving

* Mixing

* Suspending

* Emulsifying

* Aerating

* Homogenizing

* Intensification of heat exchange

Stirring allows for the homogenization of mixable liquids and the stir-up of solid particles in liquids. Differences in temperature or concentration are balanced more efficiently during stirring. Additionally, the stirring of liquids speeds up the dissolution process and increases the speed of chemical reactions. Stirring is widely used in schools and universities as well as the biotechnology, chemical, pharmaceutical and food industries. Wherever chemical products are produced and processed, you will find stirring.

Classic stirring is a convenient mixing process when the liquid's movement or low shearing demands can be met by that particular application.

WIGGENS's product portfolio of laboratory stirrers stands out due to its various stirring techniques, tools, drives and range of speeds.

Stirring can also be combined with other processes, such as heating, tempering and measuring.

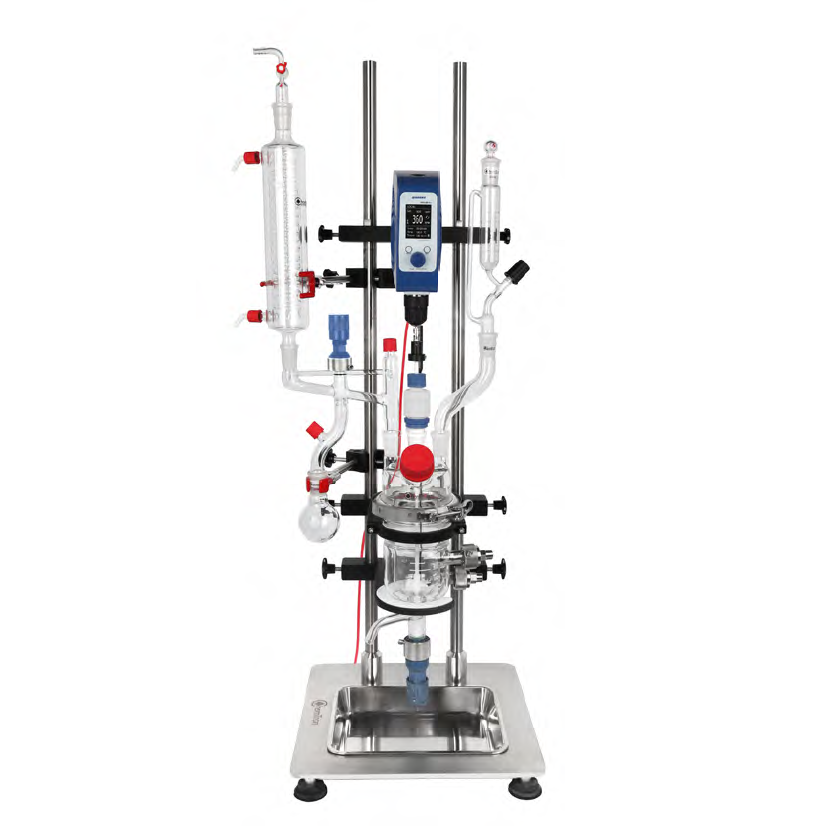

Bench top reactor, all-in-one, jacketed, 250ml

Max. reaction volume recommendation:250ml

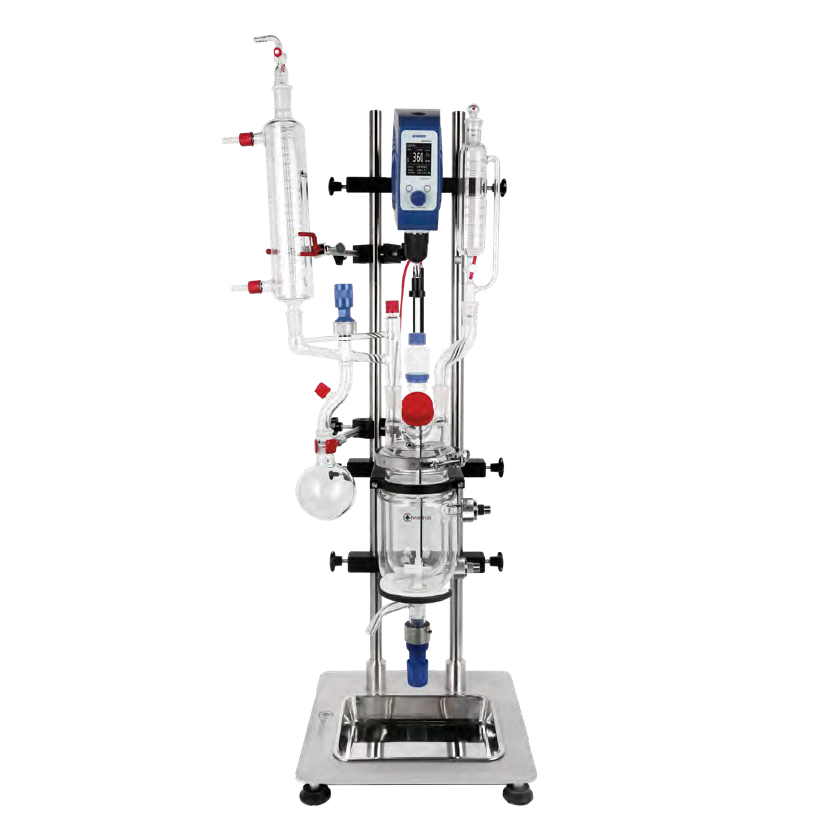

Bench top reactor, all-in-one, jacketed, 500ml

Max. reaction volume recommendation:500ml

Bench top reactor, all-in-one, jacketed, 1000ml

Max. reaction volume recommendation:1000ml

Bench top reactor, all-in-one, jacketed, 2000ml

Max. reaction volume recommendation:2000ml

Bench top reactor, all-in-one, jacketed, 5000ml

Max. reaction volume recommendation:5000ml

Hydrogenation Reactor

Including six different volume of vessels, from 9 to 335ml

Hydrogenation Reactor

Including two different volume of vessels, 950ml and 1850ml

Placa de calentamiento por infrarrojos

Temperatura máxima:550℃;Potencia de calentamiento:1200W

Placa de calentamiento por infrarrojos

Temperatura máxima:550℃;Potencia de calentamiento:1800W

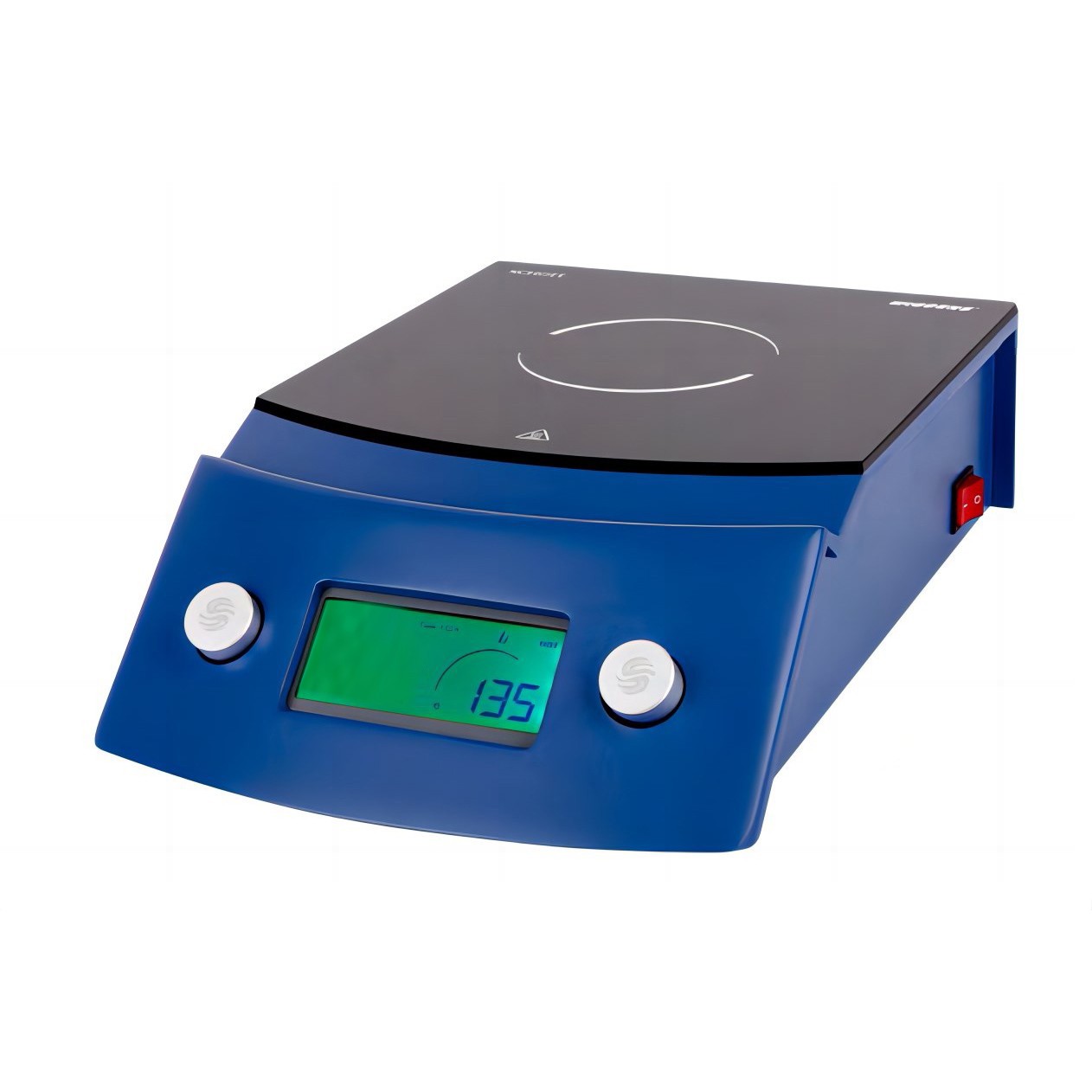

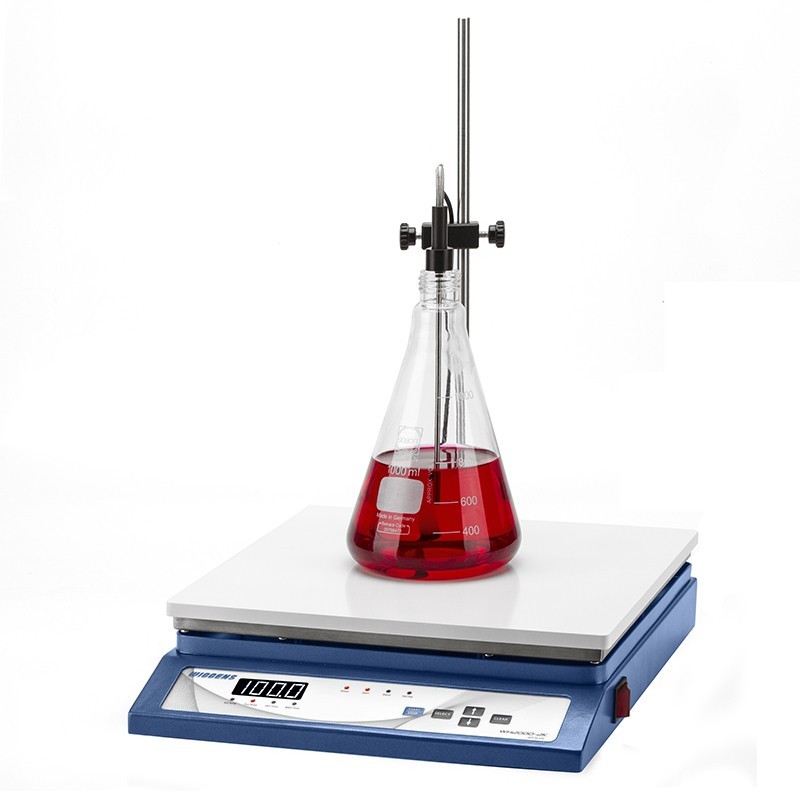

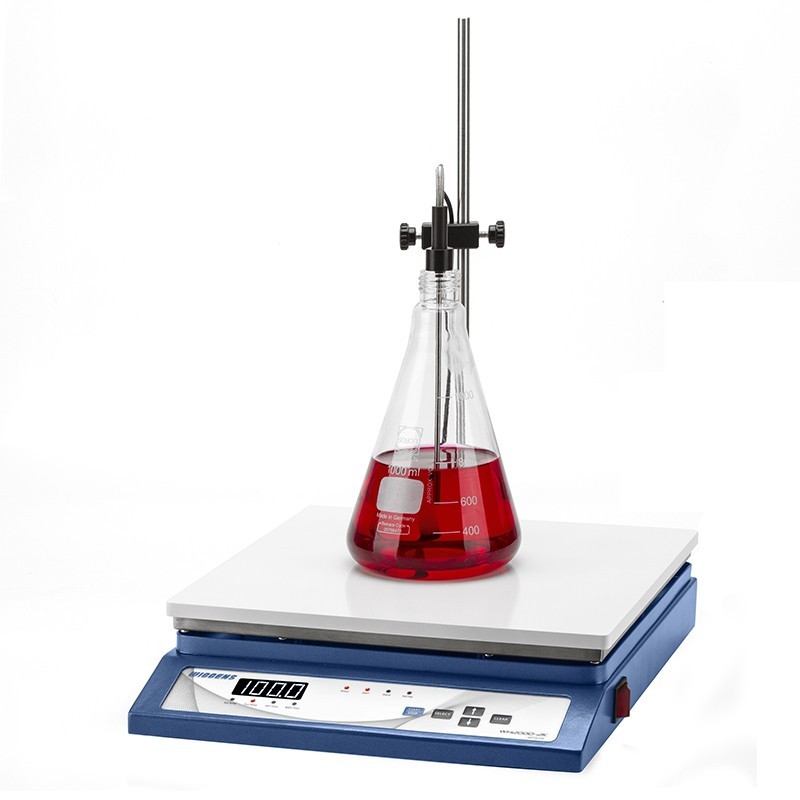

Placa de calentamiento digital

Temperatura máxima:300℃;Potencia de calentamiento:680W

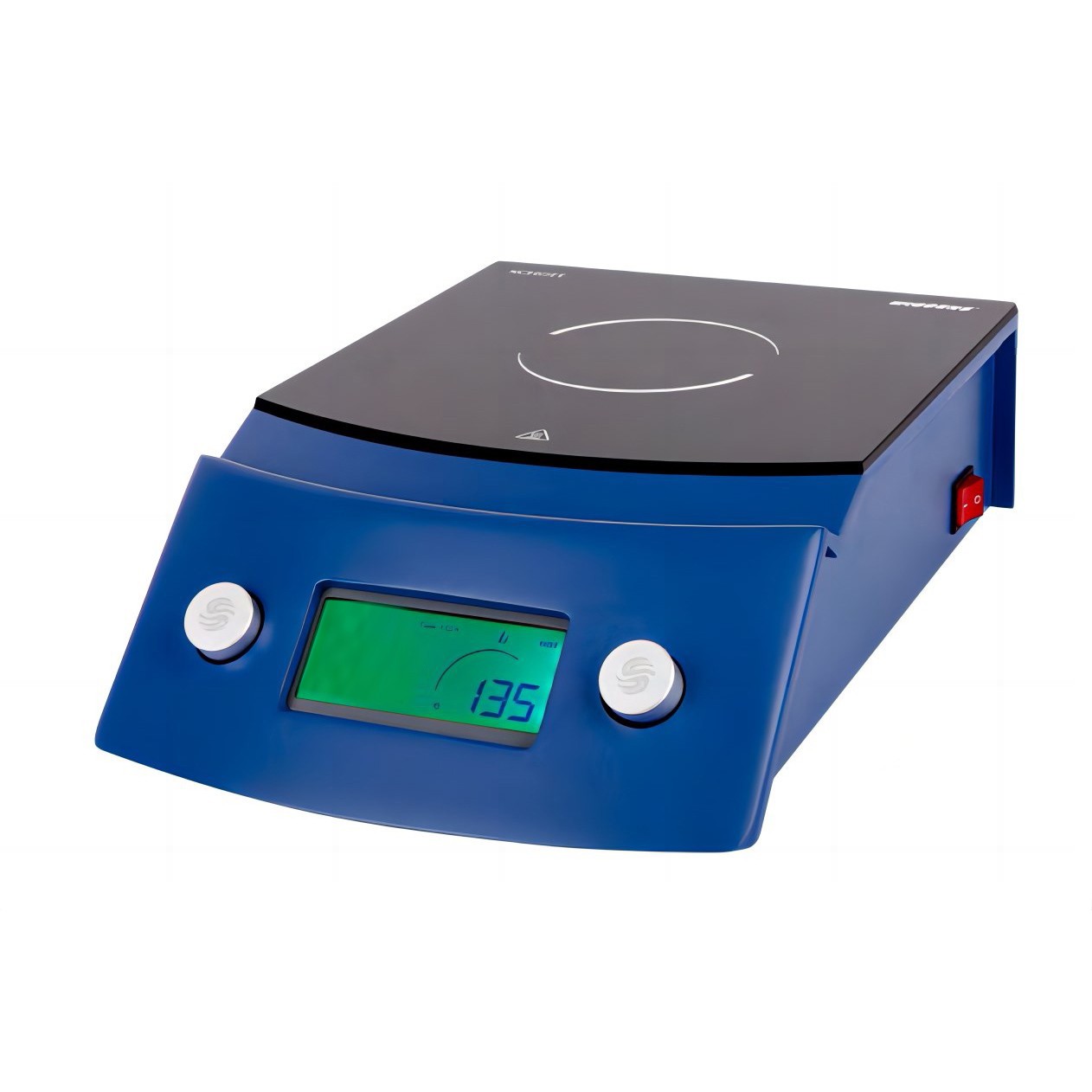

Placa de calentamiento digital

Temperatura máxima:300℃;Potencia de calentamiento:1000W

Placa de calentamiento digital

Temperatura máxima:300℃;Potencia de calentamiento:1500W

Los agitadores de hélice de la serie WOHS

Rango de velocidad:I:30~600rpm /II:601~3000 rpm

Los agitadores de hélice de la serie WOHS

Rango de velocidad:I:20~360rpm /II:361~1800 rpm

Los agitadores de hélice de la serie WOHS

Rango de velocidad:I:60~1200rpm /II:1201~6000 rpm

Agitador con alta velocidad y alto par

Rango de velocidad:30~600 (I);601~3000 (II)

Regulador de agitador magnético

Función de control:Controla cuatro agitadores para agitar a la misma velocidad

Agitador con alta velocidad y alto par

Rango de velocidad:20~360 (I);361~1800 (II)

Regulador de agitador magnético

Función de control:Controla cuatro agitadores para agitar diferentes velocidades

Agitador con alta velocidad y alto par

Rango de velocidad:60~1200 (I);1201~6000 (II)

Agitador superior controlable a distancia

Rango de velocidad:30~600 (I);601~3000 (II)

About Contact Statement Privacy Policy

Copyright © 2026 WIGGENS CO., LTD. All rights reserved.